by Stephen Parsons | Oct 4, 2024 | Uncategorized

Yes, it is that time again – where did the summer go? Well, for us at least 7-12 hours a day for close to two months was taken up building our new “greenshed” –...

by Stephen Parsons | May 27, 2024 | Uncategorized

We’ll have Big News coming soon as we begin our journey into craft skills training. We have been doing workshops for various community groups for some time, but will soon be offering half-day, one-day and extended training packages for one-on-one, small group...

by Stephen Parsons | Dec 3, 2023 | Uncategorized

We acknowledge the many challenges that face our world and our populace these days. Wars, intolerance, and climate change all present uncertainty and fear for all of us. We choose to be hopeful in the face of diversity, and wish that you all can find a time of...

by Stephen Parsons | May 3, 2023 | Design, Quilting, Strategy, Woodworking

“It’s not a learning exercise” said the event coordinator. She was trying to “school” me on why I shouldn’t help my fellow club members of the Atlantic Woodworkers Association (AWA) discover that her clients, a group of interior...

by Stephen Parsons | Dec 15, 2022 | Uncategorized

As 2022 comes to a close, we look back at the year recognizing that there are at least as many great and good opportunities as there are challenges happening in the world around us. We are hopeful that good people and positivity from emerging generations will continue...

by Stephen Parsons | Jan 14, 2022 | Inspiration, Woodworking

Am I crazy to feel good about recovering unsold stock? Our friends at Eastern Shores Gallery are moving shop in 2022! While they get organized and set up, they have decided to return all inventory to the various artists they represent, to save them the effort of...

by Stephen Parsons | Dec 10, 2021 | Uncategorized

As we enter the season of giving and charity, we wish to you, our customers, collaborators, and supporters a peaceful holiday filled with joy and love and – as far as you can, safely, in this difficult time – the companionship of friends and family...

by Stephen Parsons | Jul 4, 2021 | Design, Resources, Technology in Art

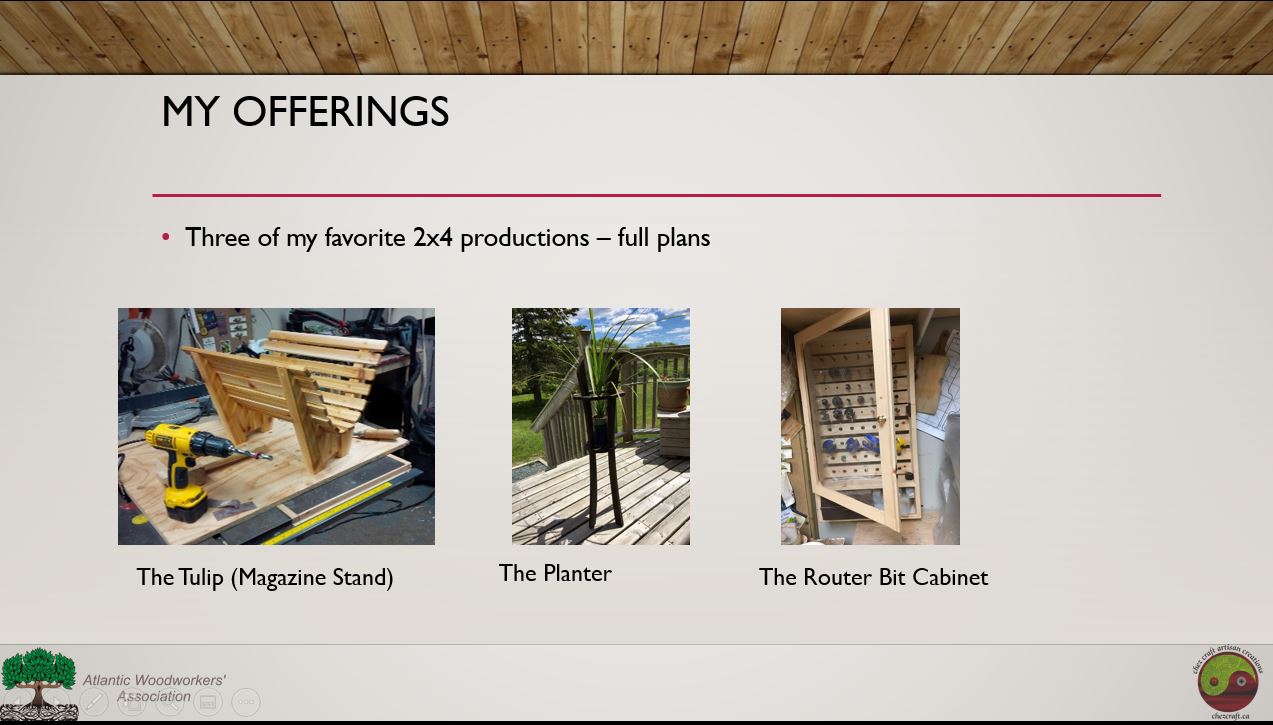

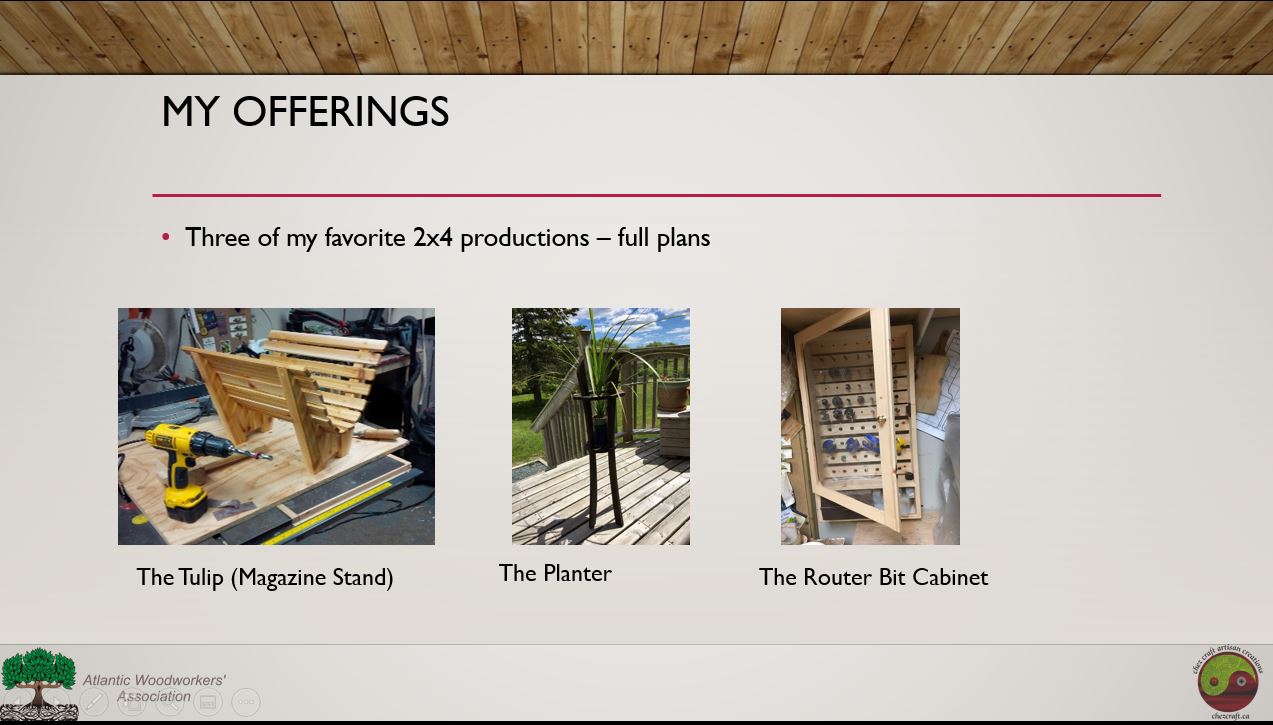

Over the past few years, I have developed a number of woodworking plans – primarily as a way to prepare for building these designs myself. In some cases they are only designs, and not plans – at least, not yet, By that, I mean they may provide detailed...

by Mary Elizabeth O'Toole | Jul 4, 2020 | Repurposing

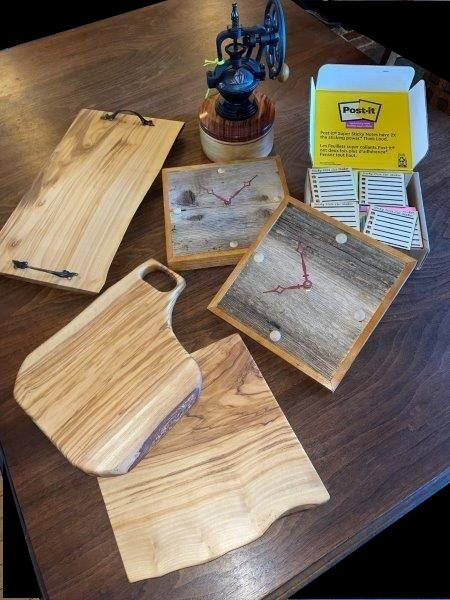

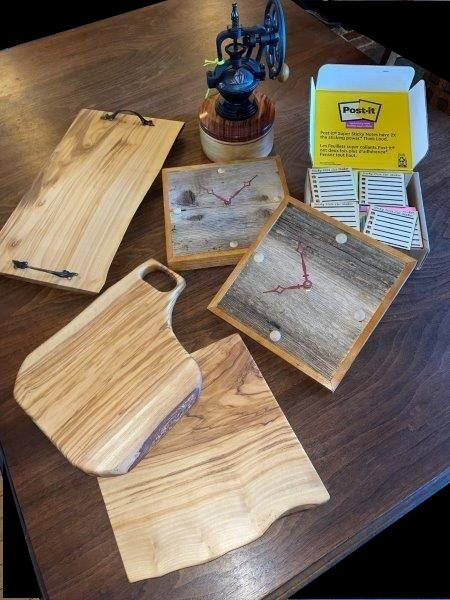

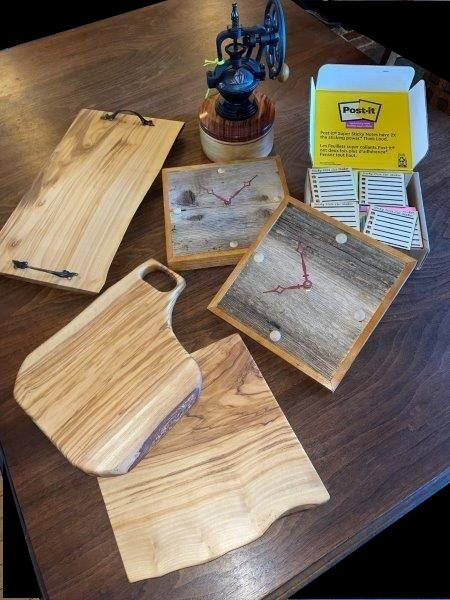

We spent most of the day in the workshop today because we are getting ready to participate with a new Eastern Shore destination, Eastern Shores Gallery. It’s opening next week in Head of Jeddore. Watch for more about this development at the beginning of next week. We...

by Mary Elizabeth O'Toole | Jul 3, 2020 | Inspiration

Revised by Mary Elizabeth from a post she originally shared in her new blog at keepthestories.ca During the early days of COVID-imposed social isolation, many thought that it would be a couple of weeks and they vowed to use the extra time to get organized and strike a...

Recent Comments